Our principle is that we should have control and mastery over the machine’s manufacturing process from start to finish.

A complete study is therefore carried out, whatever the project being launched, whether for standard machines or special machines.

Our machining and precision welding subcontractors are all local companies that provide us with the responsiveness we need.

All of our mechanical, pneumatic, electrical and electronic components are made in Europe in order to guarantee the required level of quality.

All our machines have a compact build so as to facilitate their utilisation, maintenance and handling.

GENERAL

Our formed section calibration tables are designed to combine robustness and easy integration of options in order to meet the most precise needs.

ADVANTAGES

Particular care is taken with corrosion-related problems so all the parts that come into contact with water are made of stainless steel and all the components are protected against any possible splashing.

In order to facilitate their installation and utilisation, our chassis remain fixed and only the calibrator support moves.

The installation of monobloc vacuum pumps to create a constant vacuum, or of vacuum-regulating pumps with variator for optimum energy consumption are part of our manufacturing standards.

All our chassis are precision-welded in order to guarantee overall stability.

More information...

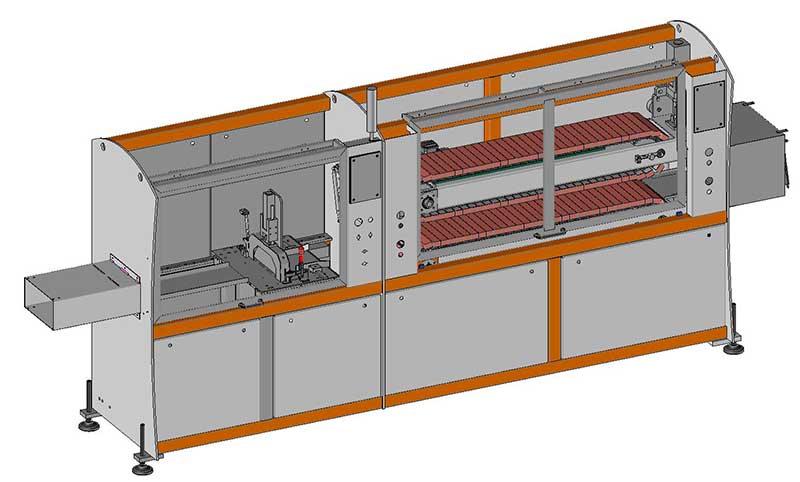

GENERAL

Two-caterpillar belt or pad haul-offs characterised by their robustness and versatility.

Oversized input / output chassis beams and sheet-metal to obtain the greatest possible stability in operation.

ADVANTAGE

• No column, upper caterpillar held in place by two cylinders at input and output to allow very wide formed sections to pass through.

Direct drive with an asynchronous geared motor mounted on each caterpillar’s axle. No maintenance.

Three possible types of control:

- Remote control desk

- Control on the front face

- Synchronous link with extruder desk

Pressure / counter-pressure setting on the upper caterpillar for thin-wall tubes and formed-sections.

Poly-V belts and pad quick-change system as an option.

For both versions, we can propose a large range of contact lengths and widths, min. and max. linear speeds as well as haul-off forces with associated torque.

All our chassis are precision-welded in order to guarantee overall stability.

More information...

GENERAL

Conventional circular saw cutting system or guillotine cutting, our machines are above all designed to obtain a better final appearance and tighter tolerances.

ADVANTAGE

• The choice of guide systems for moving the products or holding them in place as well as the reinforcement of moving mechanical parts ensure overall stability and a long life.

• The cutting trolley movements are either pneumatic or motorised with slaving to the product’s linear speed in the case of high production rates and / or tight tolerances on the cutting length.

• Adjustable pneumatic up / down movement for the circular saws.

• Motorised blade up / down movement in the case of guillotines for cutting thick walls requiring great force.

• Blade resistance-heating with temperature setting to facilitate the passage through the product.

All our chassis are precision-welded in order to guarantee overall stability.

More information...

Single-station or double-station semi-automatic winding machines for continuous coiling of flexible or semi-rigid tubes and formed sections.

Winding on reels with quick-lock system or drums with adjustable inner diameter and width for making coils.

Pneumatic opening / closing valves make it possible to disengage the inner core and extract the finished coil.

Winding precision is guaranteed by:

- Drums driven by asynchronous motors with variable-frequency drives. Winding torque regulation using an ultrasonic tensioner or by constant tension.

- Precise spooling with UHING drive or motorised movement slaved to the linear speed.

Precision-welded chassis and high-load directional wheel ensure stability and versatility.

More information...